Auxetic materials, properties and applications for a wearable capacitive technology

The objective of this work is to study the possibility to use a cheap material to build a capacitive wearable sensor, that is able to detect the difference between a transversal and longitudinal applied stress. The main idea is to change the dielectric layer of a capacitive sensor with a type of materials able to increase the thickness during a tensile load, known as auxetic materials.

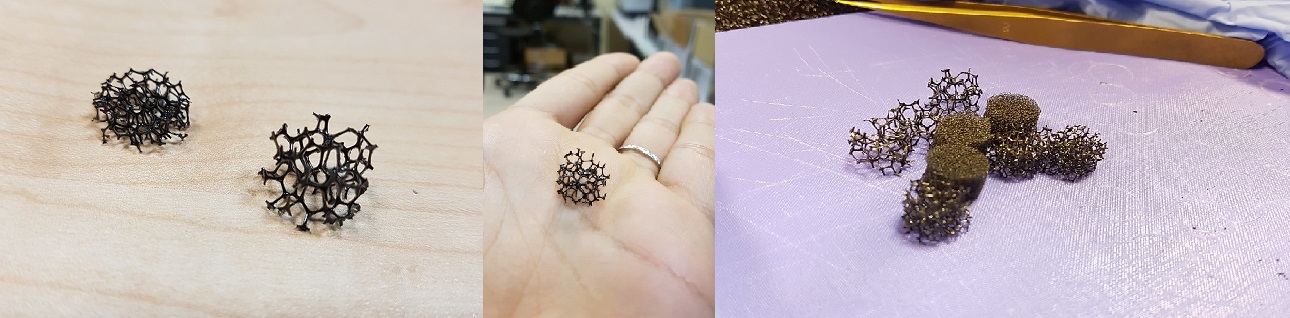

These materials and their structures are accurately described from the history of auxetic discoveries and a list of auxetic known materials is reported. Among these we find the polyurethane PU foam, that we choose as an ideal candidate for our capacitive sensor, because it's possible to transform the common PU into an auxetic one through a thermal compression process.

Main auxetic geometries are examined followed by a description of some mathematical parameters, such as Young's modulus and Poisson's ratio. The unique properties of auxetic materials are carefully examined with many applications in different areas like military defense, textile industry, biomedical sector, security, sensors and design.

The state of the art of wearable technologies is presented and their characteristics are defined, showing interesting applications in the field of medicine. Capacitive sensors and their operating principle are defined, and two applications are analyzed: touch screens and flexible artificial skins for robots.

The last part ends with the mechanical characterization of a PU sheet and its next auxetization. This process is outlined and measurements of the auxetic effect are discussed.

Download the thesis (plus LaTex source code):

Auxetic materials, properties and applications for a wearable capacitive technology.pdf

Social links